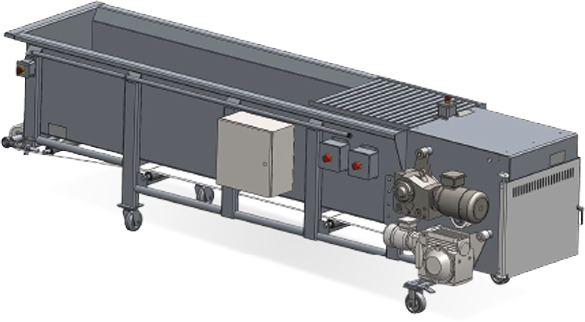

DOUGH FEED

- HYGENIC DESIGN MEETS ANSI Z 50.2 STANDARDS

- MULTIPLE WIDTHS AVAILABLE

- DESIGNS FOR COOKIE, CRACKER, GRANOLA, BREAD, BUN AND ROLL DOUGHS

- ENGINEERED TO CUSTOMER SPECIFICATIONS

Advantech will evaluate your dough handling needs, and our engineering department will work with your engineering group and/or your project team to develop the most appropriate solution to your dough handling needs.