The oven is the heart of any bakery or restaurant.

Without which it is impossible to run your food business. While many commercial bakery ovens are on the market, choosing the right one that fits your needs is very important and can seem overwhelming. Having a little knowledge about the size of your kitchen, your needs, and budget can help you choose a commercial oven that fulfills your needs and requirements.

Here are the factors to consider before choosing the right commercial bakery oven:

Oven and Types:

Convection Ovens: Convection ovens are a good choice for any size business. They run on a fan that blows hot air and cooks the items evenly and fast. Widely available for countertops and floors and ideally used for making bread, desserts, meat dishes, and other bakery food items

Commercial Ovens Or Accelerated Ovens: These are the most preferred ovens for their record cooking time under one minute. These ovens are used in fast-food chain restaurants to heat frozen food at a faster rate.

Steam Ovens: These ovens are a good option for a commercial kitchen to cook a wide range of food such as rice, fish, vegetables, and meat. This type of oven works best with restaurants that exclusively offer seafood that is grilled or steamed.

Combination Ovens: These are a combination of steam and convection ovens and are available in great space-saver size. Though expensive, they are high in demand because they use both moist and dry heat to cook the food which is why food cooked in these ovens are moist inside and crispy outside.

Cost Of The Oven:

You can always choose the oven that fits your needs as well as your budget. If you are easy with your budget, you can always get the most expensive and advanced commercial bakery oven for your food business. If you are super tight with your budget, it’s always advisable to compare the cost and features of various types available before you purchase.

Design And Build Of The Oven:

The main factor to consider before even choosing a commercial bakery oven is if it is designed to run on gas or electricity. Some may have gas hookups in the kitchen or only electric or some may even use both. So please be mindful of the design and build of the oven.

Warranty:

While running a food business, you really need a commercial bakery oven that is reliable and most efficient. So make sure the product you want to buy has a long warranty period to fix any issues and also cater to replacement if it fails in the long run.

Conclusion:

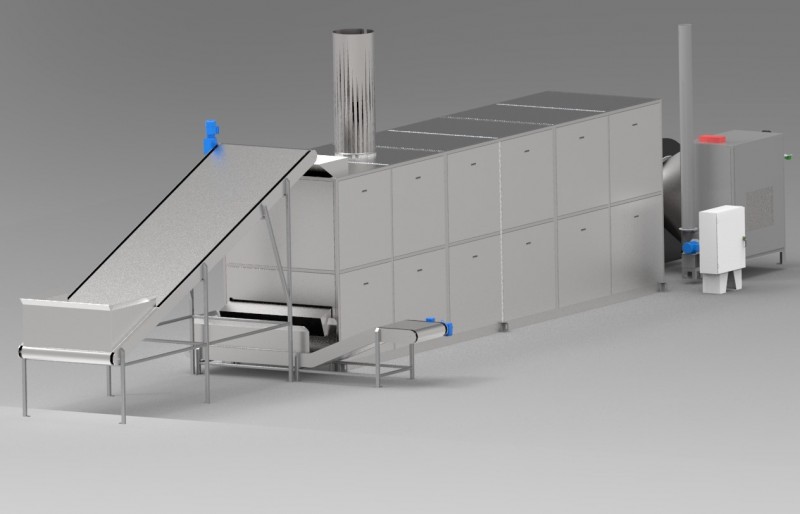

Consider the above-cited factors before you choose a commercial bakery oven that fits your business needs. We at Advantech offer a wide range of commercial bakery ovens for the best price to keep you within your budget. Reach us today to get more information on the various commercial and industrial bakery systems that are available with us.